Metal Roll Forming Machines Steel Forming Machines Steel Roll Former

Basic Info

| Model NO. | tile making machine |

| After-sales Service | After-Sales Service for Whole Life |

| Warranty | 2years |

| Tile Type | Colored Steel |

| Certification | CE, ISO, BV |

| Condition | New |

| Customized | Customized |

| Usage | Roof, Wall, Floor |

| Transmission Method | Electric |

| Name | Tile Roof Sheet Making Roll Forming Machine |

| PLC | Delta |

| Motor | Siemens |

| Pump | 4kw |

| Working Speed | 10-18m/Min |

| Material Thickness | 0.25-0.8mm |

| Safety Cover | Available |

| Chain | 1.5 Inch |

| Encoder | Chint |

| Machine Weight | Around 4t |

| Color | Any Color |

| MOQ | 1set |

| Delivery Time | 30 Working Days |

| Weight | 4-8tons |

| Transport Package | Nude |

| Specification | 15*1.35*1.2m |

| Trademark | RFM |

| Origin | Hebei China |

| HS Code | 84552210 |

| Production Capacity | 1000sets/Year |

Product Description

Metal roll forming machines steel forming machines steel roll former

Description

Metal roll forming machines steel forming machines steel roll former,840/860/900 Metal Roofing Sheet Making Machine Roll Forming Machine Cold Galvanizing IBR Tile Making Machinery China is design for color steel roof sheet roll forming,whole line consist manual decoiler,main forming machine,control box,hydraulic pump and run out table1.The whole line working speed is about 18m/min.,max working speed could be 30 meters per minute.2.Feeding material width should be confirmed before machine design .the width are changeable,3.Material thickness normal range are 0.3-0.8mm.if you have any special request on material thickness,we should discuss in advance .4.Both three and four waves are suitable for the line.we can design the machine based on buyer's profile drawing.5.Final sheet embossing is avaliable.we can different embossing rollers on various pattern and drawings.6.Pre-cutting are provided as you want.

Product Description

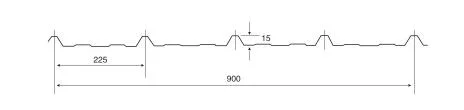

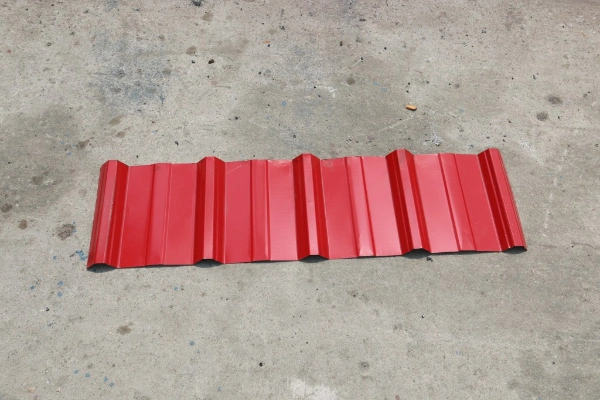

1.Product drawing and sample drawing:

2.Main equipment:

Decoiler | 5 or 10T,manual or hydraulic powered. |

Main machine | 11 stations forming rollers,chain drive. |

Hydraulic pump | 4kw. |

Control box | Delta PLC and frequency. |

Run out table | Height adjustable |

Tool box | For operate tool and spare parts. |

3.Direction for use

860 roofing sheet making machine sheet metal forming machine ibr roof sheet forming machine

1.Put all necessary parts on the right location,make the ground falttening.

2.Connect electric wires,use 6-8 mm² support line and keep grounding.

3.Fill hydraulic oil in the pump.not too full,three quarters are ok.

4.Feed raw materil into the machine slowly,make it run smoothly then automatic.5.Pay attention to final sheet collection,do not scretch it or hurts people.

Detailed ImagesMain machine photo:

Spare parts:

Packing& Shipping

860 roofing sheet making machine sheet metal forming machine ibr roof sheet forming machineNormal standard is nude,easy damage parts are covered with plastic film or wooden frame.we can also pack the machine based on customer's special requests. We fix the bottom of the container with triangular wood,the machine is fixed with steel wire to the container.

After Sales Service

1.We can design operate language based on customer's mother tongue.2.We provide 24 hours online service to solve any questions .3.Our three experienced engineer are prepared for your local installation .4.We provide for free sapre parts for you.5.We can slod buy suitable testing material for customer's easy operation.6.Customer can send their workers here study to to use and operate the machine.

Company Profile

Feixiang and Feitian roll forming machinery is a china manufacturer of metal steel cold roll forming machines, bending machines, cutting machines, and slitting machines. It is a division of its parent company, Xingbo International.Feixiang was founded in 1997 and is the oldest roll forming machine maker around today in the north of china. Its history includes the first double layer color steel roll forming machine,the first high speed interchangeable C U keel roll forming machine,the first gear drive with water cooling cable tray roll forming machine created by Mr.Fu in 2005. In 2013,they first successfully developed high speed rotary punching machine ,which highest speed could be 100m/min,makes the company got government recognition.The company marketed overseas its first roll forming machine in 2006 and established relations of cooperation with customers from over 80 countries all around the world. Feixiang has built up a reputation for designing high-quality, high-speed ,safe and cost-effective cold forming and bending equipments .They have become a status symbol for high productive capacity and the safe and easy operate. The company is synonymous with technical and has been involved with several famous international exhibition since 2008.The company currently has 2 invention patents, 1 utility model patents,has been accepted by the 1 invention patents, 2 utility model patents. Feixiang says keeping customers satisfied is " at the heart of the Feixiang roll forming machinery customer-care philosophy" .

FAQ

Q1. What's your payment terms and delivery time? A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms like L/C are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.Q2. Do you have after-sales support? A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world. Q3. Do you sell only standard machines? A3: No, most of our machines are built according to customers specifications, using top brand components.Q4. What will you do if the machine is broken? A4: We provide 24 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.Q5. Can you be responsible for transport? A5: Yes, please tell me the destination port or address. we have rich experience in transporting.Q6. How to visit your company? A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour). 2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can meet you.